Lighthouses: The Megatrends Shaping Factories of the Future

As a new era of innovation in manufacturing emerges, it promises to multiply our capacity to work smarter, more efficiently, and more seamlessly through the use of technology.

Many companies are already piloting high-tech initiatives in manufacturing, but few have managed to scale to realize significant economic and financial benefits. Those that have triumphed are hailed as ‘lighthouse factories’ — securing market-leading positions in the industrial sector.

These front-runner production sites are prime examples of how the implementation of emerging technologies can create a more prosperous and sustainable world through new levels of efficiency in manufacturing.

With smart sensors, robotics, and edge technologies right at our fingertips, manufacturers have the necessary tools to move beyond pilot purgatory, bridging the gap between blueprint ideals and beacons of industrial success.

The Lighthouse Defined

Lighthouses are industry leaders redefining production benchmarks. They serve as real-world examples of what we can expect the future of work to look like as well as the type of production approach that will drive global economic growth.

Lighthouses are the factories that have adopted innovative technologies to transcend from the proof of concept (PoC) phase to integration at scale, realizing significant financial and operational benefits. By placing the customer at the center of process design and operations, these factories improve both the initial purchase experience as well as use over the entire product lifecycle.

To classify as a lighthouse, a factory must meet high standards across 3 categories, although the parameters used for measuring success may differ from one application to another:

1. Impact

Measured by the successful integration of several use cases

2. Scalability

Measured by how well an asset handles change in workload, network usage, response time, and throughput

3. Performance

Measured by changes in management, capability building, and return on investment

What Makes a Lighthouse: Enabling Technologies

Core technologies — ML, DLT, and IIoT — form part of the lighthouse business strategy to ensure agile continuous improvements across the entire production system and end-to-end value chain.

Lighthouse manufacturers are interconnecting digitized components with AI to schedule, monitor, and improve output quality. As big data analytics and programming algorithms improve the manufacturing process, early adoption of emerging technology gives forward-thinking businesses the chance to leap ahead of their competitors. Being a first-mover and early adopter of modern technology guarantees a large share of industry benefits, whilst businesses that are slow to follow will inevitably miss out.

We are already seeing a significant gap between companies that adopt AI within the first 5-7 years and those that follow or lag behind. Front-runners in AI adoption can expect a cumulative 122% cash flow change, while ‘followers’ see a significantly lower impact of only 10% cash flow change.

Other moonshot technologies — ambitious and exploratory ideas with long-term profitability in mind — change the economics of operations by proposing radical solutions through the use of breakthrough technology.

Leading manufacturers are gaining a further competitive edge by optimizing their production system, increasing the productivity and quality performance of their operations. These companies prioritize innovation across the entire value chain, developing improved offerings by way of new products, services, customization, and shorter lead times.

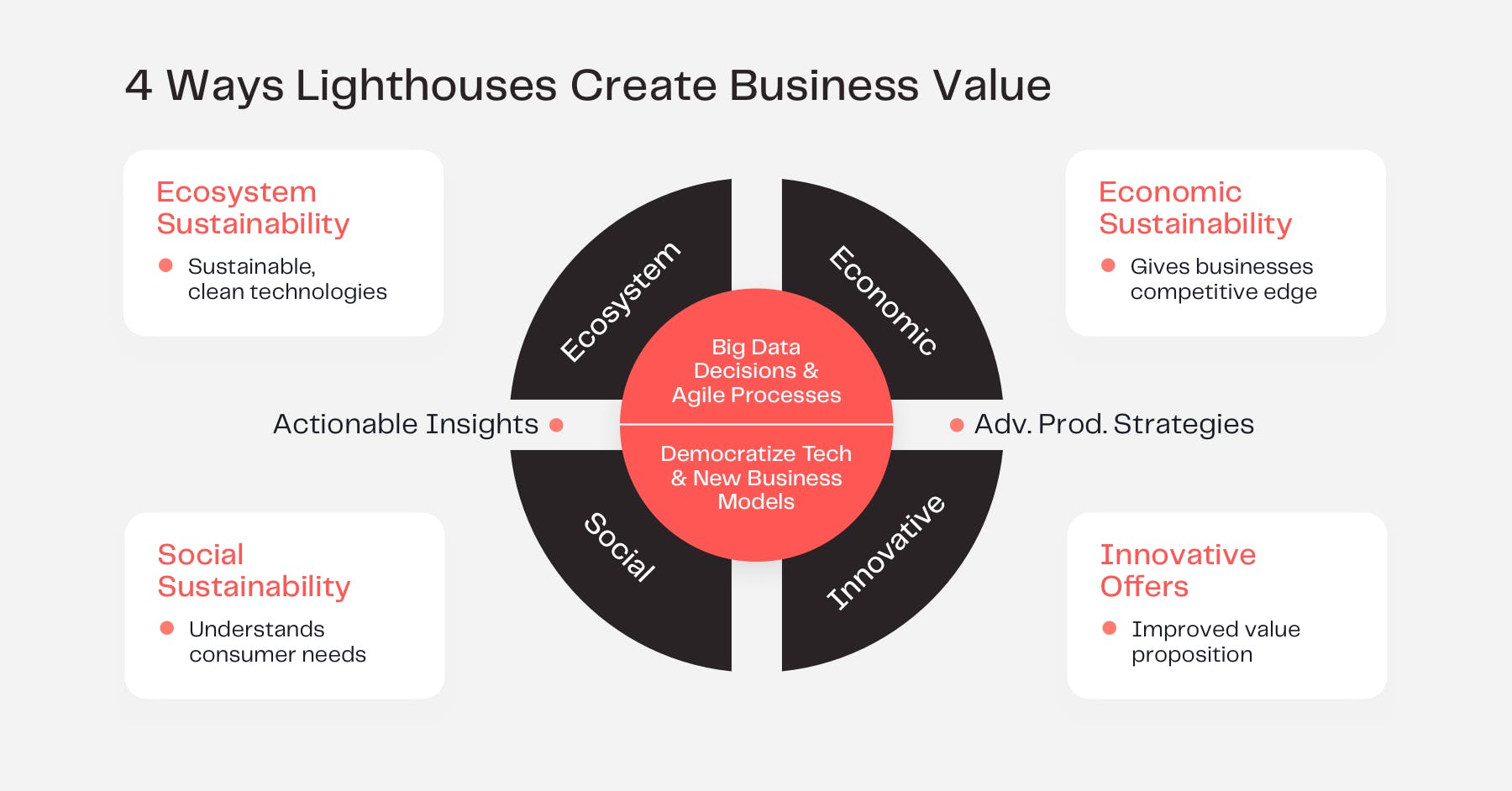

Lighthouses are creating business value in four distinct ways:

1. Big-data decision making

Business decisions derive from data analysis and pattern recognition

2. Agile processes

Encourage cross-functional collaboration and fast, continuous iterations

3. Democratized technology

Think of technology as an ecosystem and prioritize connectivity to eliminate data silos across processes

4. New business models

Develop profitable and resilient “source-make-deliver-consume-reintegrate” products and services

Innovating Ahead: 3 Manufacturing Megatrends to Follow

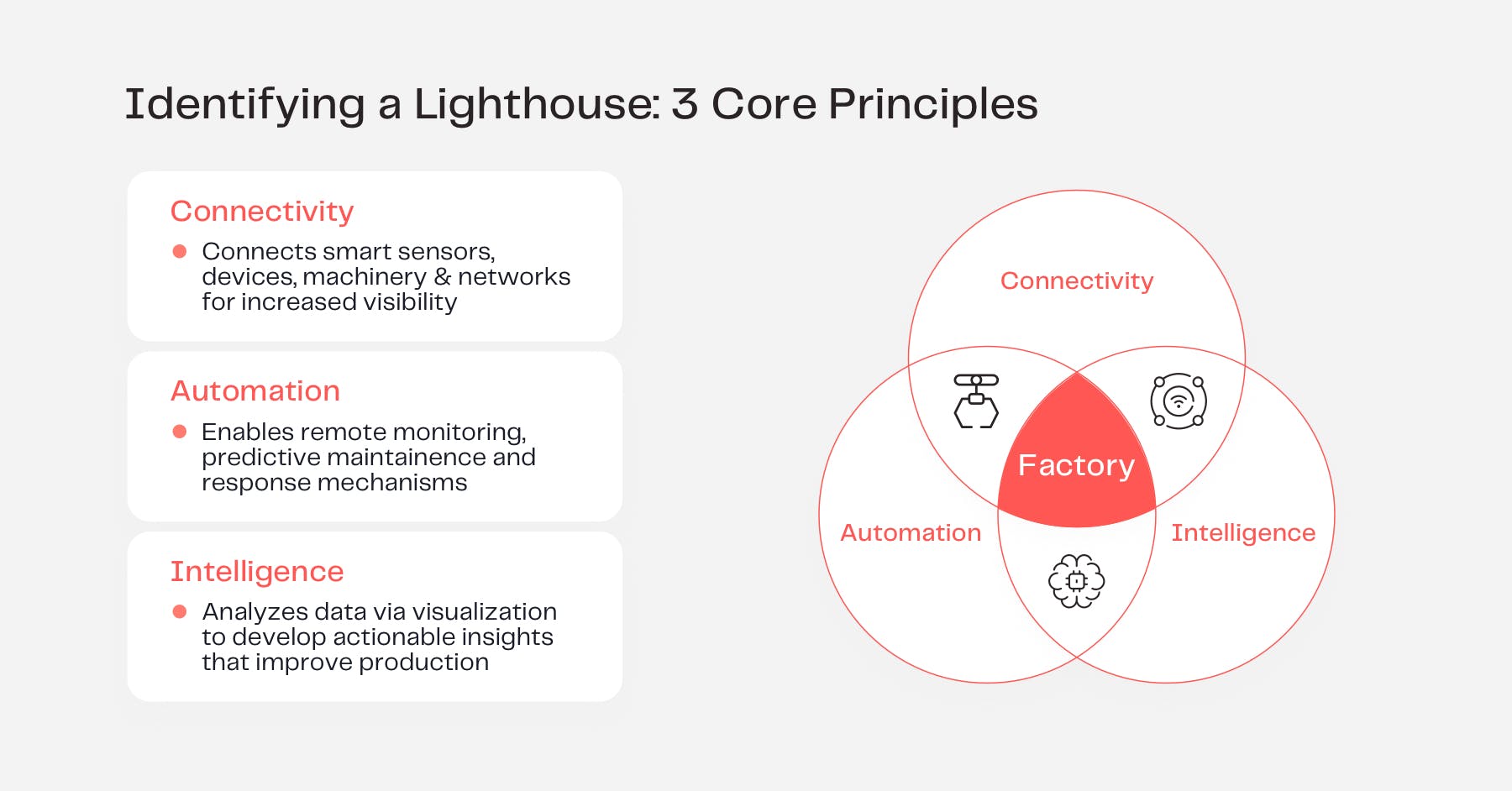

Three technological megatrends are morphing industrial factories into lighthouses of the future: 1) connectivity; 2) automation; and 3) intelligence. If the manufacturing sector is to benefit the economy, technologies and digital capabilities must be adopted at scale and across the entire value chain.

Driving the Next Economic Growth Engine: Who is Responsible for Action

Lighthouses are transforming the nature of production to make it less repetitive and more efficient. Production sites that have embraced these megatrends (connectivity, automation, and intelligence systems) at scale offer a blueprint for other manufacturers to follow.

Unlike previous eras of drastic industrial change, the adoption of new and emerging technologies in today’s manufacturing sector can generally be implemented on existing infrastructure.

Lighthouse factories are open innovators and collaborators. For laggards and slow adopters, the responsibility for action lies with both the public and private sectors. By taking learnings from existing beacon sites and coupling this knowledge with incremental advances in applying technology to existing infrastructures, factories can follow the same trajectory that leads to the emergence of lighthouses.

A tri-sector innovation system comprising business, government, and the social sector will play a defining role in driving lighthouses in the Machine Economy forward.